-

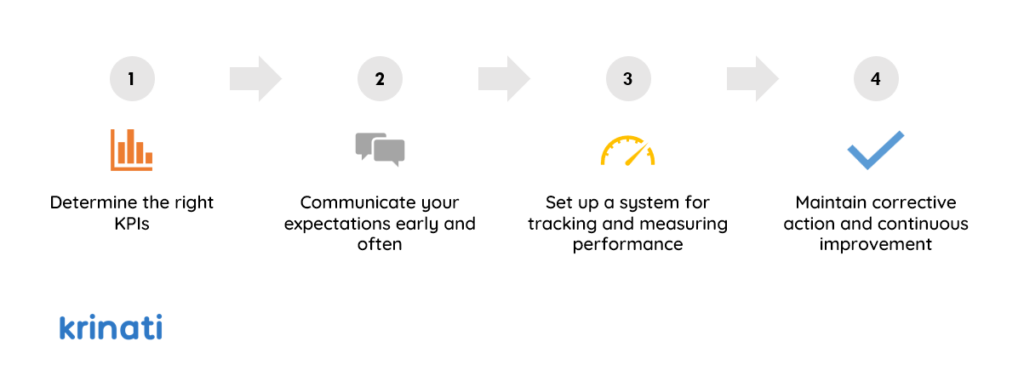

4 Steps to Make Supplier Performance Management Work for you

Why is Supplier Performance Management important?

Supplier performance management is important for a number of reasons:

- It helps ensure that goods and services are delivered on time and meet quality standards. This is especially important in industries where timely delivery and high quality are crucial, such as in the manufacturing or healthcare sectors.

- It allows organizations to identify and address issues or problems with their suppliers before they have a negative impact on the business. This can help prevent delays, reduce costs, and improve overall efficiency.

- It helps organizations make better-informed decisions about their supplier relationships. By tracking and analyzing supplier performance data, organizations can determine which suppliers are the most reliable and cost-effective, and prioritize their relationships accordingly.

- It can help organizations build stronger relationships with their suppliers. By working closely with suppliers to understand and address their needs, organizations can foster mutual trust and cooperation, which can lead to long-term partnerships.

Here are 4 steps to make supplier management services performance work better for your business.

1) Determine the right KPIs

While you establish the practice of monitoring supplier performance, the first step is to understand what you will measure. Determine the exact metrics you will use to evaluate and track supplier performance. This will help you make more informed decisions when evaluating and assessing supplier performance.

The metrics you use should be specific, measurable, and realistic. This will ensure that you’re able to accurately measure your suppliers’ performance and make changes when necessary. You should also take into account the impact each measure has on the overall performance of your business.

Typical performance KPIs include:

- On-time delivery

- Quality of product or service – SLA adherence or rejections on the assembly line

- Pricing terms

- Sustainability & Environment

- Risk & Stability – Reputation, Insurance, Financial Stability

2) Communicate your expectations early and often

Once you’ve determined the performance measures for tracking supplier performance, it’s important to be proactive in communicating with suppliers. Make sure that suppliers are aware of the metrics that will be used to measure their performance and how their performance will be tracked. This includes communicating your expectations about quality, cost, delivery timelines, and other key performance metrics. Ensure that suppliers are given enough information to allow them to make the necessary changes to meet your goals.

This proactive approach to communication with suppliers will create a culture of trust and ensure that everyone involved in the process understands their role in achieving success.

Additionally, you should establish regular intervals for evaluating supplier performance and make sure the data is collected and communicated with all stakeholders at these intervals.

3) Set up a system for tracking and measuring performance

Keeping track of and measuring supplier performance is important. A supplier performance scorecard is a great way to track and measure performance over time and make necessary corrections.

When setting up a supplier performance scorecard, there are several factors you should consider. For each measure, you should assign a numerical value that corresponds to a certain level of performance. Then, at regular intervals, you should gather data about how your suppliers are performing against these measures and determine the overall performance score for each supplier.

Choose a method for storing and organizing data, such as a spreadsheet or specialized software. For smaller organizations, spreadsheets work great. For more complex needs, specialized software esourcing solution is available that can help with tracking and analyzing supplier performance data. These solutions may offer features such as automated data collection, real-time reporting, and the ability to track multiple suppliers and KPIs. By doing this, you can easily track trends in performance and make changes where needed.

4) Maintain corrective action and continuous improvement

Continuous improvement is a key part of supplier performance management. This means continually working with your suppliers to review current performance, discuss areas for improvement, and set new goals and objectives.

By taking necessary corrective action, you can ensure that your suppliers meet the standards you have set for them.

If a supplier is consistently underperforming, it’s important to have a plan in place to address the issue and take steps to improve performance. This could include reducing the order size, providing extra training or resources, or finding an alternative supplier.

For suppliers that consistently perform to set expectations, you need to put strategies in place to maintain their continued involvement with the organization; most often requiring one-on-one meetings with management personnel from both parties involved.

Original Source: 4 Steps to Make Supplier Performance Management Work for you

-

Why Suppliers Should Not Fear Reverse Auctions

Reverse auctions are a great tool for buyers to save money, but many suppliers tend to be apprehensive about participating in them. Suppliers do not like participating in reverse auctions because they are typically viewed as a race to the bottom in terms of pricing.

There are more apprehensions which we will articulate in this article. We will also take a look at the remedial measures a buyer must take to ensure auctions are competitive and the best bid is placed by the most capable supplier.

Understand suppliers’ apprehensions about participating in reverse auctions

When it comes to participating in a reverse auction, suppliers are wary about who else will be in the pool of participating vendors. Suppliers fear that they will be pitted against unqualified or inexperienced vendors who will try to undercut their prices, compromising the quality of the product or service.

Incumbent suppliers may also worry about the fairness of the auction. They may feel that their knowledge of the buyer’s needs and the standing relationship they have with the buyer are not given enough consideration. This can make them feel devalued and uncertain about the outcome of the bidding process.

Large and established suppliers may further worry that a reverse auction only takes into account price, and does not measure their ability to deliver on the project or meet customer needs. They feel the auction does not adequately differentiate between different companies, especially if one has more experience or resources than the other.

Finally, suppliers will be wary of poor buyer behavior while conducting reverse auctions. Buyers tend to place phantom bids, not award business as per prior commitment or tend to negotiate further with the supplier post-auction. Such buyer actions demerit the effort and cause mistrust among the suppliers.

Communicate the benefits of reverse auctions to the suppliers

While supplier apprehensions have merit, the truth is that reverse auctions offer several benefits to the participating suppliers. Buyers need to ensure they inform suppliers of these benefits as well as other insights important to them.

One of the biggest benefits of reverse auctions is the level playing field it creates for all participating suppliers. They can see their competitive positioning vis-a-vis other suppliers and place further bids accordingly. They can trust the system instead of the words of a buyer! In other words, all suppliers have an equal chance of winning the business.

Reverse auctions open up new opportunities for several suppliers. The auction process allows suppliers to reach a much wider audience of buyers than they normally would have access to. This can lead to more business and larger contracts for many suppliers, reducing their sales costs.

Also, while winning the auction is often the primary goal, there are other benefits to participating in reverse auction sourcing. If a supplier does not win, they still gain insights into what their competitors are offering and the market value of their products.

Effectively manage every apprehension of the suppliers

Supplier apprehensions must be proactively addressed. If suppliers feel that reverse auctions are detrimental to trust-based relationships with the buyer, this needs to be managed on priority.

Communicating the award scenario to the suppliers prior to the auction and adhering to it builds trust. How many suppliers will be awarded the business? How much share of the business can the best bidder expect? Would there be any further qualifying steps for a new supplier? Greater the clarity on the outcome, the higher the competition from suppliers.

Explain to suppliers that you are not on a mission to find the ‘cheapest’ supplier. On the contrary, past performance and better capability are valued and factored into the auction. This ensures that the most capable supplier wins, not the cheapest on price alone.

If you have done a pre-qualification of suppliers prior to the auction, go ahead and communicate this to all the participating vendors. This will demonstrate the integrity and seriousness your company has when it comes to reverse auctions.

Summary

In summary, buyers must acknowledge that suppliers are wary of participating in reverse auctions. Their prior experience with other buyers, perhaps from the same industry, also set their perception regarding the process. These apprehensions are critical to be addressed because supplier participation is critical to the success of any online auction.

Krinati offers Program Management Services tailored to assist you in executing a successful eSourcing solution program. To do this, we focus on communicating the right message to suppliers and addressing their apprehensions. We also train users on the dos and don’ts of eSourcing as well as providing event management for sourcing events.

Original Source: Why Suppliers Should Not Fear Reverse Auctions

-

How to Achieve Success with Strategic Sourcing: Top Best Practices

How do you achieve success with strategic sourcing? What do you need to do to be successful with strategic cost reduction? This article outlines some of the best practices on how to effectively perform strategic sourcing, so you can achieve your goal of lowering your costs without sacrificing the quality or reliability of your supply chain.

What is Strategic Sourcing?

Strategic sourcing is a process used by organizations to identify and secure the best possible channels of supply for their goods and services. It involves analyzing, negotiating, and managing all aspects of the procurement process, from product selection to delivery. The goal of strategic sourcing is to maximize business value and savings by reducing costs, increasing efficiency, and improving supplier relationships.

The success of strategic sourcing requires a joint strategy between the buyer and supplier. This entails a comprehensive analysis of the buyer’s strategic spend – what they spend money on and how much they spend – to identify areas where cost savings can be achieved. It takes into consideration business objectives, quality standards, and compliance requirements.

Once areas for savings have been identified, an effective supplier management strategy needs to be implemented in order to brainstorm ideas, setting expectations, and ensuring that performance criteria are met. In addition, there should be ongoing communication between the buyer and supplier to ensure that the relationship remains beneficial for both parties.

By using strategic sourcing techniques, organizations can realize significant savings on their total spend and form lasting partnerships with trusted suppliers.

Understanding Your Spend Dynamics

When it comes to strategic sourcing, understanding your spend categories is key to success. One of the best ways to get started is to use the Kraljic Matrix, which classifies spend into four categories: Bottleneck, Leverage, Non-Critical, and Strategic.

Bottleneck items are high-value, high-risk products that require close supplier management. Leverage items have high unit costs, allowing for cost reduction opportunities. Non-Critical items are low-cost products that are easy to replace and don’t require specialized attention. Lastly, Strategic items can create a competitive advantage, so they require careful selection and maintenance of suppliers.

Once you understand how each item fits into the classification, you can define expectations for each category and develop effective strategies for cost savings and supplier management.

For Bottleneck items, you may need to reduce lead times. For Leverage items, focus on cost reduction with long-term contracts or purchasing volume discounts. For Non-Critical items, streamline your procurement process to increase efficiency and save time. Finally, for Strategic items, ensure that you’re selecting the right suppliers to meet your organization’s needs.

Each of these levers, if successfully implemented, can impact a holistic, positive change in the supply situation.

Understanding Your Internal Needs

Internal cross-functional needs refer to the requirements or goals of different departments or functions – Quality, Manufacturing, IT, Finance, After-Sales, Marketing, etc) within an organization that need to be considered. Engage with representatives from these departments to understand their specific needs and requirements. This could include factors such as budget constraints, technical specifications, regulatory compliance, and delivery timelines.

Inputs from past sourcing events are important to look at – both successes and failures alike – so you can make informed decisions this time around; what succeeded last time versus what might not work next time.

Conducting Market Research

As part of this market research process, you need to gain an understanding of your organization’s existing supplier base and the industry dynamics at play. This data can be used to evaluate current esourcing platform strategies and develop new ones. By collecting this information, you’ll gain the insights necessary to make the best decisions for your company and reduce costs in the long run.

The Structure-Conduct-Performance (SCP) model is a wonderful tool to conduct this step. The model highlights the tight link between market structure, market conduct and market performance. Once you have conducted your research, you will be able to outline the high-level approach for each strategic category.

Creating a Request for Information (RFI)

One of the first steps is to gather gather information about a potential supplier’s capabilities and capacity to meet your requirements. A request for information (RFI) is a tool that is used for this purpose. The RFI questionnaire typically includes a series of questions related to the supplier’s capabilities, such as the types of products or services they offer, their production capacity, their quality management systems, and their delivery and logistics capabilities.

By collecting this information, you can make an informed decision about whether to engage with the supplier and potentially enter into a business relationship. An RFI questionnaire can also help to identify any potential gaps or weaknesses in the supplier’s capabilities, which can be addressed through further discussions or negotiations.

Creating a Request for Proposal (RFP)

An RFP esourcing platform plays a primary role in streamlining the process of soliciting bids and creating a level playing field for all suppliers. An RFP clearly outlines the details of the project, such as the quantum of goods or services needed and any specific features or requirements.

For strategic items, the pricing information solicited from suppliers shouldn’t be just on Unit Price. The endeavour here is to identify as many cost factors that impact the pricing of an item or service. Say you are buying millions worth of Castings. Ask every supplier to provide an cost breakdown right from the purchase of raw material to manufacturing overheads to packaging and shipping. Having such rich information from several suppliers arms you with excellent negotiation power.

Evaluating Proposals and Shortlisting Suppliers

When it comes to strategic sourcing, evaluating proposals to RFIs and RFPs and selecting the right suppliers for negotiation is an essential part of the process.

The RFI questionnaire can be weighted and the responses scored by a cross-functional team. This not only ensures the evaluation is objective but also feedback from other stakeholders are factored in the supplier evaluation.

The RFP response evaluation includes a comparison of the pricing of the participating suppliers.

To sum up, when evaluating proposals, there are several key factors that should be taken into account, including cost reduction, quality assurance, delivery speed, and customer service. It is important to consider both short-term and long-term cost savings when comparing bids. Quality assurance measures should also be taken into account to ensure that the products or services meet your standards. And customer service should also be taken into consideration to make sure that any issues or support needs that arise can be addressed quickly and effectively.

Final Negotiation and Contracting

The suppliers that meet the capability needs and are reasonable on pricing need to be negotiated with. In this negotiation phase, it’s important to clearly define expectations and make sure all parties are in agreement with the terms of the agreement.

Once a supplier is selected for award, it’s important to carefully manage the contract or agreement to outline all of the terms and conditions of the partnership. Additionally, it’s important to create metrics and performance benchmarks that will be used to measure the effectiveness of the supplier over the life of the contract.

Monitoring and Improving the Supplier Performance

Finally, effective supplier management is essential for regularly evaluating suppliers based on performance metrics and price. It’s also important to provide adequate communication between the business and suppliers, as well as provide incentives for meeting expectations and goals.

Regularly evaluating suppliers and looking for ways to improve costs through strategic sourcing can have a big impact on a business’s bottom line. With the right approach, businesses can gain better control over their supply chain and improve their profitability.

Original Sourcing: How to Achieve Success with Strategic Sourcing

-

How To Build Credibility With Suppliers For Your Eprocurement Initiative

It is up to the buyers to enforce practices in their sourcing process that build trust with suppliers. These practices assume greater importance when companies resort to eProcurement.

Companies that have been successful in building a credible eSourcing initiative tend to adopt the following practices. These practices have been shown to encourage suppliers to participate in a fair and competitive manner.

Buyers agree to the following steps that establish credibility

- Detail out the requirements clearly. While the incumbent suppliers understand even the unstated requirements, the new ones wholly rely on the RFP for clarity. So explain the specifications and service level expectations as clearly as possible.

- Award only to the suppliers who bid online. Manage suppliers who don’t like to bid online with great urgency and importance. A handful of such suppliers can derail the entire eSourcing platform initiative.

- If lots (containing multiple line items) have been created and suppliers are bidding at a lot level, then award at the lot level only. Do not attempt to optimize the award at a line-item level later. This is unfair to suppliers who tried their best to be competitive at the lot level.

- Do not simply eliminate suppliers who tend to quote too high or too low. Give them a second look. Discuss the pricing with them. It is possible that they have misunderstood the specifications or requirements.

- Communicate the award scenario clearly. When suppliers bid aggressively, they need to know what’s up for grabs. Buyers must state the number of suppliers that might get awarded and the share of the business that they can win depending on their competitive position.

Some additional best practices while conducting an online auction

- Qualify suppliers before the auction. It is advisable not to have unqualified suppliers compete with qualified ones. It does not make a level playing field and will definitely cause issues during the award.

- Award business at prices bid online. Do not negotiate offline with suppliers, especially with the best-bid suppliers. While it may seem rational to do so, every supplier will get to know of this practice and they will not honor future auction procurement.

- Do not place phantom bids during a live auction. This is an unethical practice and can have serious ramifications. Buyers do this thinking that suppliers will not get to know. But when they do, they will refuse to bid online again.

Encourage suppliers to conduct themselves fairly. They must…

- Respond completely and honestly. The qualifying questions have been asked for a reason that needs to be responded to in its entirety. Do not shortlist suppliers that have provided incomplete documentation.

- Submit all bids as legally valid ones. Do not give lame reasons later as to why a submitted bid must not be considered.

- Bid online and as aggressively as possible. Suppliers must understand that there is no scope to negotiate prices offline. They must bid online aggressively to win the business instead of using other means to convince buyers of their capability.

eProcurement does not mean that everything happens online. Supplier management is more important in this case. Understanding and proactively addressing supplier concerns to bid online is vital to the success of an eProcurement initiative. Spend quality time managing suppliers offline while the bidding happens online.

Original Source: How To Build Credibility With Suppliers For Your Eprocurement Initiative

-

What Is An RFP And Why Is It Important To Digitalize It?

What is an RFP?

A Request for Proposal (RFP) represents a document or a sourcing stage where proposals are solicited from suppliers or solution providers.

The Buyer uses the RFP to state the requirements of the goods or service being procured, the terms and conditions of the engagement, the vendor evaluation criteria, and most importantly the bidding sheet. This bid sheet outlines the quantum of goods or services and suppliers need to quote the price for the same.

RFPs apply to all types of spend – indirect, direct and capex. Every sourcing process needs an RFP in some form or other; with varying complexity depending on the nature of the item being sourced.

3 key aspects of an RFP that underline its importance

1. RFPs precede the ‘negotiate & award’ stage and hence need to be managed from that perspective

An RFP is followed by a negotiation process after which the business is usually awarded to the most competitive supplier in terms of price, capability and service.

In an online eSourcing platform scenario, RFPs precede auctions and hence set the basis for the starting price for every supplier. If multiple suppliers have responded within a narrow price range, the chances of a successful auction are high. Note that If prices are high, it is not advisable to rush into an auction without understanding the reasons behind high pricing received from the suppliers.

In addition, negotiation happens with qualified suppliers only. Hence the RFP must solicit all kinds of information for buying teams to achieve that.

2. Supplier Management is critical once RFPs are floated

Supplier responses to an RFP are the initial indicators of the supplier interest and eventual success of the sourcing project. While the buyer may think the business is exciting for every supplier, it may not be the case. A large steel furniture company put out a bid for USD 30M worth of fabricated steel. While this seemed a phenomenal business for any new vendor, it required many of them to invest significantly to meet this demand. The terms & conditions didn’t address this aspect and hence the RFP received a lukewarm response.

Supplier participation is key. If an RFP is floated to 15 vendors and only 2 of them respond, it’s a cause for concern. Either the specs are wrong or over-designed or the suppliers have misunderstood certain aspects of the RFP. Reaching out to them proactively and addressing their concerns is vital.

3. Standardization of RFPs helps to lower cycle times

Studies show that companies spend 30% of their sourcing cycle time in drafting RFPs. Many times, sourcing teams tend to recreate RFP content rather than reusing content from previous RFPs.

In addition, standardization helps in reducing time-to-publish and also allows teams to proceed with greater clarity.

Standardization of pricing bid sheets (computation of activity costs or landed costs), terms and conditions, qualifying questions, etc. help a great deal in speeding up the process.

What are the benefits of digitalizing RFPs?

It is common for many sourcing teams to only adopt online auctions as part of an esourcing initiative. RFIs and RFPs continue to be manual though. At Krinati, we believe this is a sub-optimal approach and greater value could be realized if RFPs are digitized and executed online too.

Online RFPs help sourcing teams achieve the below.

1. Reduced time to create and publish RFPs

Templates help in creating and publishing RFPs in minutes.

Say there is a qualifying questionnaire used to purchase chairs for a new office. This questionnaire can be saved as a template and reused for the next sourcing event. Let’s assume that the team made some omissions in the previous sourcing cycle – they forgot to ask for after-sales support for the chairs and the time for resolution. Since questionnaire templates can be modified on-the-fly, the event content remains updated and available at the time of publishing the sourcing event.

2. Improved supplier management and collaboration

Supplier bids should be analyzed as soon as they are submitted online. How does one supplier fare vs the others? Have suppliers responded to all the line items? Are there any line items that haven’t received any response? It is critical to evaluate the RFP when it is still live because all the analysis done post the response due date does not serve the same purpose.

3. Greater Savings

Suppliers tend to trust a system more than the words spoken by a buyer. Competitive RFPs display the rank and/or leading bid to suppliers as soon as they submit their response. As a result, this sets in some competition and suppliers submit several bids while the RFP is live.

This works great when items are bought for the first time or when there is an auction procurement to follow. RFP responses tend to be in a narrow range which sets up an auction very well.

4. Compliance and audit-friendliness

We all agree that this is one of the most audited processes in any organization. Auditors need to know — Were 3 bids were sought? Which suppliers did not participate? Why did they decline? Who approved the award? Who qualified the supplier (evaluation scores)?

Online RFPs provide this much-needed compliance that keeps the internal audit team happy!

Original Source: RFP eSourcing Platform

-

6 Reasons Why Reverse Auctions Fail to Deliver the Desired Results

Reason 1: Inviting unqualified suppliers to the auction event

Auctions should immaculately be the final step in the negotiation process. Negotiating with suppliers post the auction is a big no-no. Also, qualifying suppliers post the auction has its drawbacks too. Assume the smallest-ranked supplier is disqualified post the transaction. The coming ranked supplier will misdoubt the veracity of the event and will probably be irritated.

Reason 2: Poor supplier management

Suppliers would much rather fight in a transparent and fair market, where their capabilities can be fairly estimated. They prefer to join the auctions with capable suppliers. They doubt an unclear selection and shortlisting process. Having a simple auction tool is critical to ensure suppliers aren’t discouraged from joining online auctions.

Some common supplier queries are the following:

- Why is the buyer even conducting reverse auction sourcing? We’ve serviced them well over the times and delivered good value, so why this change?

- Are we fighting against suppliers that have poorer manufacturing facilities compared to ours?

Reason 3: Having price as the sole criterion for the award

This point can not be stressed enough. Not just the suppliers, but internal stakeholders within the association ( from Quality, Manufacturing, and After- Sales) too need to be assured that the procurement team isn’t out to confirm deals with the cheapest suppliers.

Hence, the repetition of the earlier point on the supplier qualification process is extremely important.

Reverse auctions too need to support this. When suppliers with varying capabilities take part in the same auction, the benefits of the more capable supplier need to be reckoned with.

Read this composition – Transformed Pricing helps in comparing prices from dis-similar suppliers – that details why Total Cost auctions are an absolute necessity.

Reason 4: Selecting the wrong category for the auction

Category dynamics play a major part in the result ( read savings) of a reverse auction. For example, opting an item with hardly any compressible margin, say sheet metal fabricated particulars, won’t deliver any measurable savings even though the spending amount may be high.

Reason 5: Unclear specifications, terms, and award criteria

Conducting online auctions assumes that precise specifications can be drawn up for the product being sourced. Having precise specifications and service prospects helps suppliers in pricing their offerings correctly, especially when the bidding gets competitive. We can not look forward to the suppliers that have been awarded the business meeting the unstated needs latterly. While the reverse auction process gets criticized for this, this frequently happens in offline negotiations too.

For commodity-driven categories, a long-term agreement without any price factoring doesn’t work.

The award criteria are an important motivator for suppliers in supplier management services. When a supplier places the lowest bid, they anticipate winning a large share of the business. So buyers need to plainly mention the intended share of the business. Will it be awarded to a single vendor? To 3 vendors? If 3, also what’s the typical share for each? If it’s a new supplier, also what’s the ramp-up period & process to achieve the stated share of the business?

Reason 6: Lack of management support

Studies show that the application of reverse auctions has better results when it has a top-down approach. With the management’s support, the following was achieved

- Supporting functions worked together with purchase teams to deliver bigger results. This encouraged invention and a focus on several cost-reduction regulators as well.

- Resistance from suppliers to involvement in online auctions was more managed. Suppliers could smell a serious buyer intent to negotiate via reverse auctions across a broad set of orders.

Krinati provides Program Management Services that help consumers achieve optimum results from their eSourcing initiative. Our eSourcing playbook helps our consumers navigate through every phase of the journey– train users, shortlist orders for cost reduction, manage suppliers, address change management, set up a review mechanism, etc.

Original Source: 6 Reasons Why Reverse Auctions Fail to Deliver the Desired Results

-

What Is eSourcing And How Can The Companies Benefit From It?

What is eSourcing?

The process of Sourcing involves looking for new suppliers, assessing their capability, comparing their products and their offerings with the demand or with the incumbent supplier’s offering, uniting with all suppliers to receive marketable bids, researching the bids, and negotiating for the optimum price & capability mix.

Depending on the strategic nature of the goods or service being sourced, some stages of the sourcing process assume more importance, say brainstorming sessions to decide on cost reduction regulators, inputs from manufacturing and quality teams on issues faced and framing an approach that addresses them.

eSourcing platform helps to digitalize the entire Sourcing process through an online platform that’s penetrated by both the buying team and the suppliers.

eSourcing result generally delivers 3 functionalities viz.

1. Request for Information( RFI)

A questionnaire that suppliers respond to. Given the strategic nature of the sourced order, the questions can be weighted and the supplier responses scored across functional teams in order to arrive at a net weighted average score per supplier.

2. Request for Quote ( RFQ) or Request for Proposal ( RFP)

Then the specifications, quantity of the particulars or goods being sourced along with the terms & conditions are transferred to the suppliers. Suppliers give marketable bids for the same. Collaboration with internal stakeholders and addressing supplier queries are done online

3. Online Auctions

The 3 fundamental types of online auctions include Reverse Auction procurement, Forward Auction, and Dutch Auction. Online deals help a buyer negotiate with multiple suppliers across multiple orders in an effective manner making the negotiation process more transparent to the supplier.

What are the benefits of eSourcing?

There are 5 crucial benefits of any eSourcing solution. It’s important for every association to articulate the benefits they seek or the problems they need to break and ensure the same is attainable using the result they’ve shortlisted.

1. Higher Compliance

Conducting the sourcing process on a common online platform rather than through emails, spreadsheets, and phone calls ensures advanced compliance. Strong inspection trails help the audit team to understand the number of suppliers participating, which suppliers declined to participate and why, who approved the award scenario, who handed what evaluation to a supplier response, etc.

2. Lower Cycle Times

There are two aspects to sourcing cycle time. One, the time is taken to produce an RFI or RFP, and two, the time is taken to award the business post-releasing the RFP. eSourcing tools allow the customers to produce and exercise templates that speed up the RFX creation process. Buyers should be able to analyze bids as soon as they’re entered and connect with suppliers immediately to reduce the time to analyze and award business.

The use of templates also standardizes processes and enables sharing of best practices between buying teams spread across locations.

3. Improved Collaboration

Collaboration is important between the buyer and other internal stakeholders within the association and externally with suppliers.

4. Lower Cost

Auctions are proven to deliver 9-11% off savings for indirect spending. This is one of the best means to test good suppliers competitively.

Competitive RFPs also display the Rank/ Best Bids to suppliers, which helps get multiple bids from a supplier without any effort. The time assigned to all suppliers to respond to the RFP say 3 days or 10 days, is more productive for the buyer.

From a supplier’s perspective, they tend to respond better to eSourcing results because they trust a system further than what the buyer verbally informs them. Supplier operation is easier. The result needs to be user-friendly not just for the buying teams but also for the supplier to log in and share in the sourcing event.

Original Source: What Is eSourcing?

-

What Is eSourcing And How Do Companies Benefit From It?

What is eSourcing?

The process of Sourcing involves finding new suppliers, evaluating their capability, comparing their products and offerings with the requirement or with the incumbent supplier’s offering, collaborating with all suppliers to receive commercial bids, analyzing the bids, and negotiating for the optimum price & capability mix.

Depending on the strategic nature of the goods or service being sourced, some stages of the sourcing process assume greater prominence, say brainstorming sessions to decide on cost reduction levers, inputs from manufacturing and quality teams on issues faced, and framing an approach that addresses them.

eSourcing helps to digitalize the entire Sourcing process through an online platform that is accessed by both the buying team and the suppliers.

eSourcing solution typically delivers 3 functionalities viz.:

1. Request for Information (RFI)

A questionnaire that suppliers respond to. Given the strategic nature of the sourced category, the questions can be weighted and the supplier responses scored by a cross-functional team in order to arrive at a net weighted average score per supplier.

2. Request for Quote (RFQ) or Request for Proposal (RFP)

Here the specifications, quantity of the items or goods being sourced along with the terms & conditions are sent to the suppliers. Suppliers provide commercial bids for the same. Collaboration with internal stakeholders and addressing supplier queries are done online

3. Online Auctions

The 3 basic types of online auctions include Reverse Auction for suppliers, Forward Auction, and Dutch Auction. Online auctions help a buyer negotiate with multiple suppliers across multiple categories in an effective manner making the negotiation process more transparent to the supplier.

What are the benefits of eSourcing?

There are 5 key benefits of any eSourcing solution. It is important for every organization to articulate the benefits they seek or the problems they need to solve and ensure the same is achievable using the solution they have shortlisted.

1. Higher COMPLIANCE

Conducting the sourcing process on a common online platform instead of emails, spreadsheets, and phone calls ensures higher compliance. Strong audit trails help audit teams to understand how many suppliers participated, which suppliers declined to participate and why, who approved the award scenario, who provided what evaluation to a supplier response, etc.

2. Lower CYCLE TIMES

There are two aspects to sourcing cycle time. One, the time taken to create an RFI or RFP, and two, the time taken to award the business post releasing the RFP. eSourcing tools allow users to create and reuse templates that speed up the RFX creation process. Buyers should be able to analyze bids as soon as they are received and collaborate with suppliers instantly to reduce the time to analyze and award business.

The use of templates also standardizes processes and enables sharing of best practices between buying teams spread across locations.

3. Improved COLLABORATION

Collaboration is important between the buyer and other internal stakeholders within the organization and externally with suppliers.

4. Lower COST

Auctions are proven to deliver 9-11% off savings for indirect spending. This is one of the best means to test qualified suppliers competitively.

Competitive RFPs also display the Rank/Best Bid to suppliers, which helps get multiple bids from a supplier without much effort. The time assigned to all suppliers to respond to the RFP say 3 days or 10 days, is more productive for the buyer.

From a supplier’s perspective, they tend to respond better to eSourcing solutions because they trust a system more than what the buyer verbally informs them. Supplier management is easier. The solution needs to be user-friendly not just for the buying team but also for the supplier to log in and participate in the sourcing event.

About Krinati Sourcing

Krinati Sourcing is an innovative solution that delivers the above benefits. Our solution is used by marquee companies globally across multiple industries. What makes us stand out from the competition is the ease of creating complex pricing sheets – be it Activity Based Cost Models or Total Cost of Ownership models. The ease of use ensures high adoption and our vaunted support services ensure every customer is successful.

Original Source: What Is eSourcing And How Do Companies Benefit From It?

-

Transformed Pricing Is Critical While Comparing Prices From Dis-similar Suppliers

Procurement teams often face a scenario where they have to compare bids from suppliers that aren’t exactly similar. What do we mean by that?

Here are some scenarios where bids received from suppliers aren’t comparable.

- Shipping costs are incurred by the buyer and are different for each supplier i.e. supplier provides goods ex-works and the buyer is responsible for the transportation of goods.

- Payment terms are different

- Quality and esourcing services levels are different

- Switching costs are incurred with a new supplier

- Preference is given to incumbent suppliers

- plus others

If we need reverse auctions to be conclusive in themselves, then they cannot be applied in such scenarios. This can be a challenge for companies trying to establish reverse auctions as a norm for supplier negotiations.

The way to address this is via Transformed Price bidding. How does that work? The bids placed by suppliers are transformed by applying ‘Price Transformation Factors’, thus normalizing the bids received from suppliers i.e. ‘Transformed Price’.

Illustration:

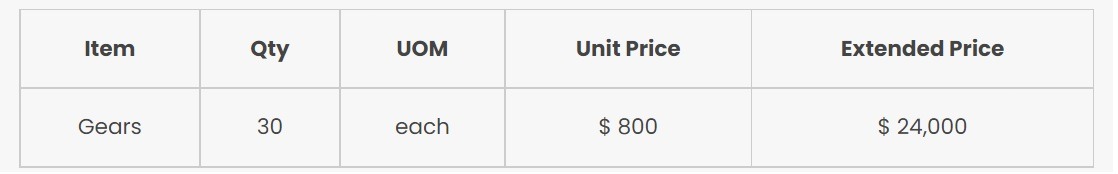

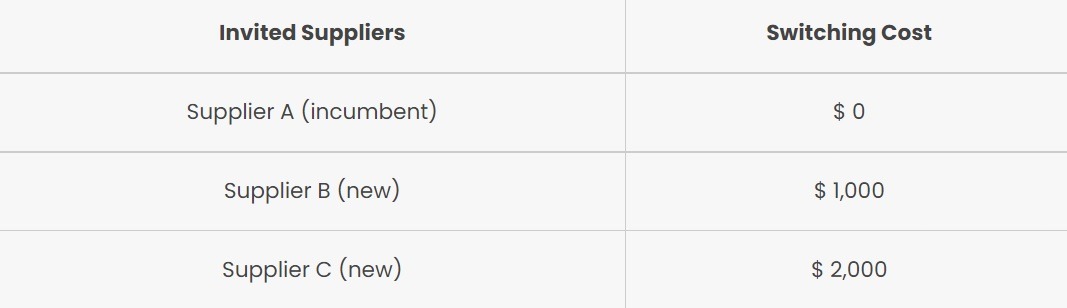

Let’s take an example of a lot of Gears being purchased from 3 suppliers.

Switching Cost is applied to a couple of new vendors, B and C. It’s not applicable to the incumbent Supplier A.

The transformation formula would be:

Transformed Price = Submitted Price + Switching Cost

Here we can see that transformation factors are applied to the prices submitted by suppliers. It does not make sense to shift to the new suppliers though their unit pricing is lower than that of the incumbent supplier.

A suggestion to teams conducting such events is to document the transformation factors and the values for each supplier along with the transformation formula being applied to supplier bids. Additionally, have these documents signed off by the relevant authority. This can be an area of internal audit in the future and the right documentation helps.

It does not end here though. The reverse transformation is then applied to compute one supplier’s bid’s view by other suppliers. In some way, this is similar to how multi-currency bidding works, just a tad more complex.

An added benefit of using Transformed Price bidding is convincing other stakeholders that reverse auction procurement is not just about cost reductions (cost is often perceived to be directly proportional to quality) and that better and more capable suppliers can be given a (fair) advantage.

A suggestion to teams conducting such events is to document the transformation factors and the values for each supplier along with the transformation formula being applied to supplier bids. Additionally, have these documents signed off by the relevant authority. This can be an area of internal audit in the future and the right documentation helps.

Original Source: Transformed Pricing Is Critical While Comparing Prices From Dis-similar Suppliers

-

6 Reasons Why Reverse Auctions Do Not Deliver The Desired Results

Reason 1: Inviting unqualified suppliers to the auction event

Auctions should ideally be the final step in the negotiation process. Negotiating with suppliers post the auction is a big no-no. Similarly, qualifying suppliers post the auction has its demerits too. Assume the lowest-ranked supplier is disqualified post the auction. The next ranked supplier will doubt the veracity of the event and will likely be peeved.

Reason 2: Poor supplier management

Suppliers would much rather compete in a transparent and fair market, where their capabilities can be fairly evaluated. They prefer to participate in auctions with similarly capable suppliers. They doubt an unclear selection and shortlisting process. Having a simple auction tool is critical to ensure suppliers aren’t discouraged from participating in online auctions.

Some common supplier queries are the following:

- Why is the buyer even conducting a reverse auction? We have serviced them well over the years and delivered terrific value, so why this change?

- Are we competing against suppliers that have a poorer manufacturing facility compared to ours?

Reason 3: Having price as the sole criteria for the award

This point cannot be stressed enough. Not just the suppliers, but internal stakeholders within the organization (from Quality, Manufacturing, and After-Sales) too need to be convinced that the procurement team is not out to sign deals with the cheapest suppliers.

Hence, the reiteration of the earlier point on the supplier qualification process is extremely important.

Reverse auction for suppliers too needs to support this. When suppliers with varying capabilities compete in the same auction, the benefits of the more-capable supplier need to be accounted for.

Read this article – Transformed Pricing helps in comparing prices from dis-similar suppliers – that details why Total Cost auctions are an absolute necessity.

Reason 4: Selecting the wrong category for auction

Category dynamics play a major part in the outcome (read savings) of a reverse auction. For example, selecting an item with hardly any compressible margin, say sheet metal fabricated items, will not deliver any measurable savings even though the spending may be high.

For a better understanding of this, read this article – To Be Updated Later

Reason 5: Unclear specifications, terms, and award criteria

Conducting online auctions assumes that precise specifications can be drawn up for the product being sourced. Having precise specifications and service expectations helps suppliers in pricing their offering accurately, especially when the bidding gets competitive. We cannot expect suppliers that have been awarded the business to meet the unstated requirements later. While the reverse auction sourcing process gets blamed for this, this often happens in offline negotiations too.

For commodity-driven categories, a long-term agreement without any price factoring does not work.

The award criteria are a key motivator for the supplier. When a supplier places the lowest bid, they expect to win a higher share of the business. So buyers need to clearly mention the intended share of the business. Will it be awarded to a single vendor? To 3 vendors? If 3, then what’s the typical share to each? If it’s a new supplier, then what’s the ramp-up period & process to achieve the stated share of the business.

Reason 6: Lack of management support

Studies show that the implementation of reverse auctions has a better outcome when it has a top-down approach. With the management’s support, the following was achieved:

- Supporting functions worked jointly with purchase teams to deliver on bigger goals. This encouraged innovation and a focus on several cost-reduction levers as well.

- Resistance from suppliers to participate in online auctions was better managed. Suppliers could sense a serious buyer intent to negotiate via reverse auctions across a broad set of categories.

Original Source: 6 Reasons Why Reverse Auctions Do Not Deliver The Desired Results

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.